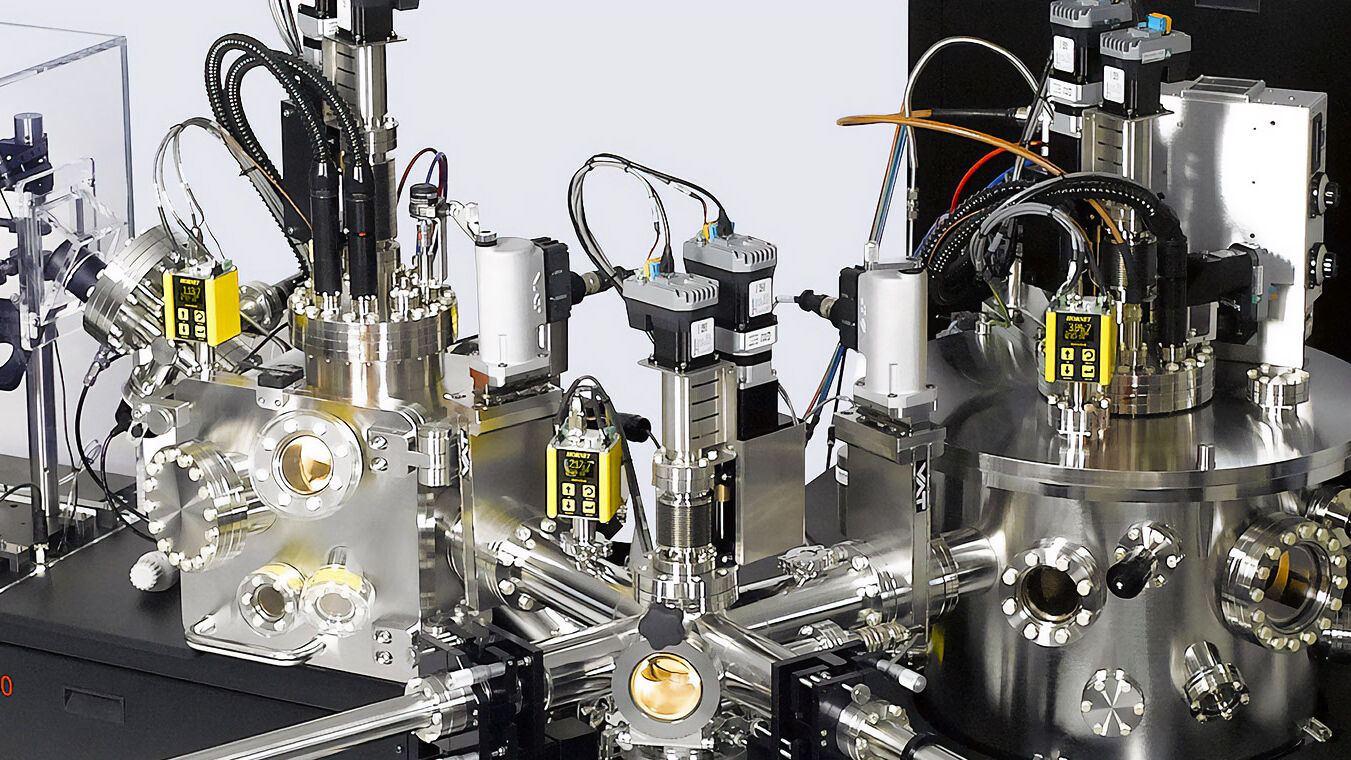

We are a Colorado, USA based company specializing in the design and manufacture of vacuum measurement and control instrumentation. InstruTech’s vacuum gauges utilize the most recent advances in vacuum gauge designs offering measurement capabilities from 2.00E-11 Torr to 1,000 Torr.

Our product portfolio of vacuum gauges and vacuum gauge controllers includes convection enhanced pirani, hot cathode Bayard-Alpert ionization, cold cathode inverted magnetron, capacitance diaphragm gauges and vacuum switches.

InstruTech’s philosophy of product offering is to design extremely reliable vacuum measurement products with multi-functional features at very attractive prices. As such, InstruTech vacuum measurement instrumentation provides significant cost savings in both the initial purchase price as well as total cost of ownership.

What we do.

- Convection enhanced pirani

- Hot cathode Bayard-Alpert ionization

- Cold cathode inverted magnetron

- Capacitance diaphragm gauges

- Vacuum switches

- Vacuum gauge controllers