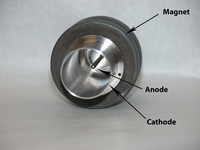

The double inverted magnetron cold cathode sensor is made up of a cylindrical cathode (the envelope) surrounding a cylindrical wire or rod called the anode. Two opposing cylindrical magnets are used to create an axial magnetic field relative to the anode and cathode. When the gauge is operating, a high voltage potential of about 4KV is generated between the cathode and anode. At sufficiently low pressures, an electron plasma is started when an electron is removed from the cathode. The plasma is a charged electron cloud which is trapped inside the magnetic field between the anode and the cathode. Electrons inside the cloud will impact a gas molecule removing an electron which creates an ion. As ions are created they will be attracted and collected at the cathode generating a current. As ions are flowing to the cathode, a proportionate number of electrons are flowing to the anode. This current is measured and is used as an indication of the gas density and pressure inside the gauge.

- 1.00E-09 to 1.00E-02 Torr

- 1.30E-09 to 1.30E-02 mbar

- 1.30E-07 to 1.30 Pa

Yes. The CCM500 is not a functional device without the InstruTech B-RAX or the FlexRax controller.

No. The CCM500 is only functional when used with the InstruTech B-RAX or the FlexRax controller.

There are no usable signals from the CCM500. The CCM500 interfaces with the B-RAX or the FlexRax controller using its own device specific serial communications. See B-RAX or the FlexRax data sheets for available output signals.

When the pressure has dropped below 1.00E-02 Torr.

Yes. You can turn on the filament manually using the front panel push buttons of the B-RAX or the FlexRax controller.

You can turn on the cold cathode sensor automatically by configuring the B-RAX or the FlexRax controller to use readings from another gauge such as an InstruTech convection gauge.

Yes. The cold cathode sensor can be easily disassembled for field cleaning.